Upon completion of discharging operations, vessel touched bottom during astern manoeuvring within a canal junction, in Amsterdam.

The outcome of the incident is remarkable. The rudder blade came in contact with the propeller, resulting in extreme deformation. Rudder blade below rudder horn pintle found bent to stbd side by approx. 40deg and rudder stock found slipped in housing by approx. 27deg. A number of propeller blades found bodily buckled by more than 90deg.

Repairs were carried out by Damen Shiprepair Amsterdam and were attended on behalf of H&M U/Wrs by our Piraeus Office Surveyors, who were involved in the project throughout, providing assistance on initial swift arrangements on repair methodology, monitoring progress / cost of repairs and reporting thereof.

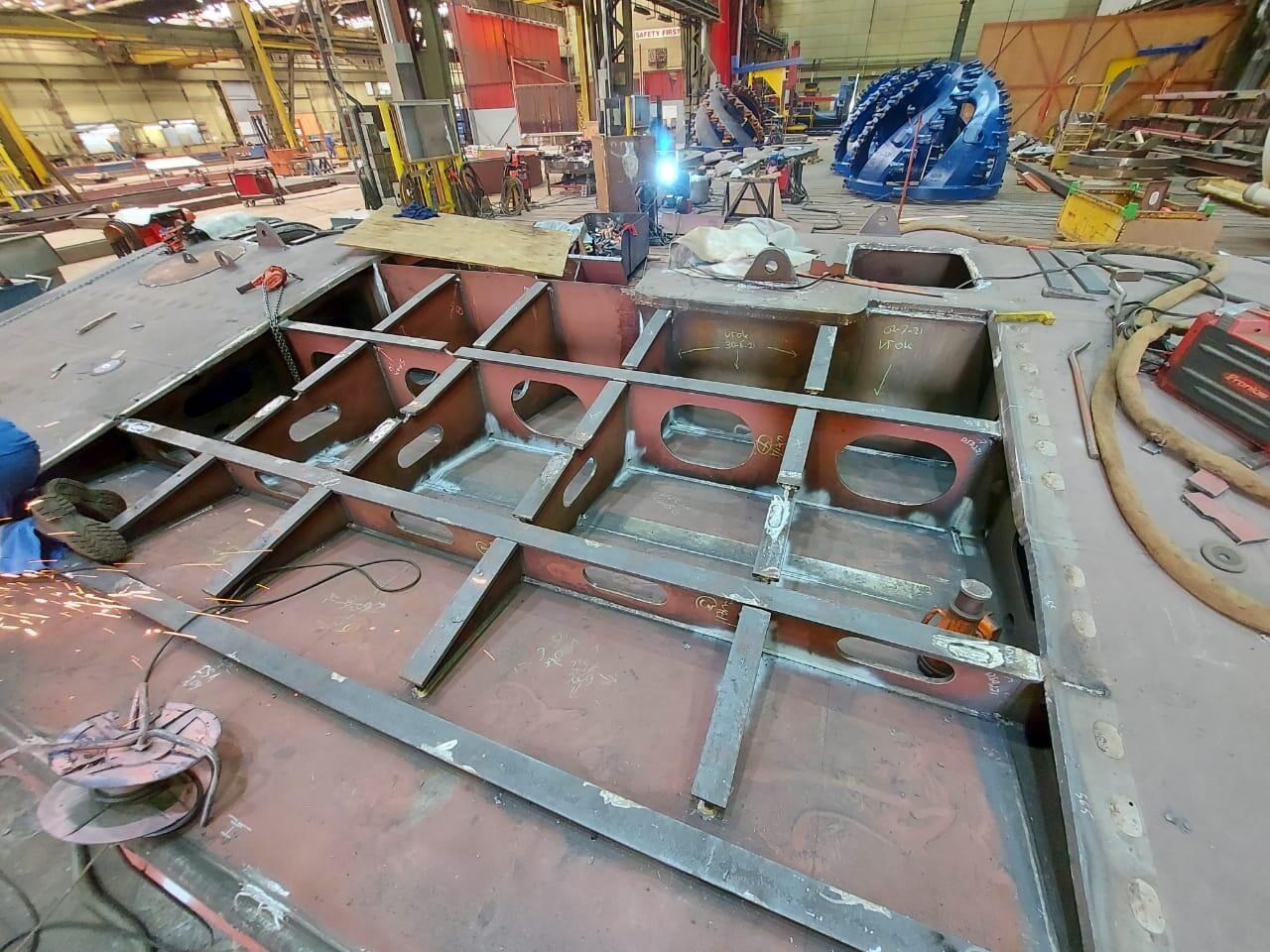

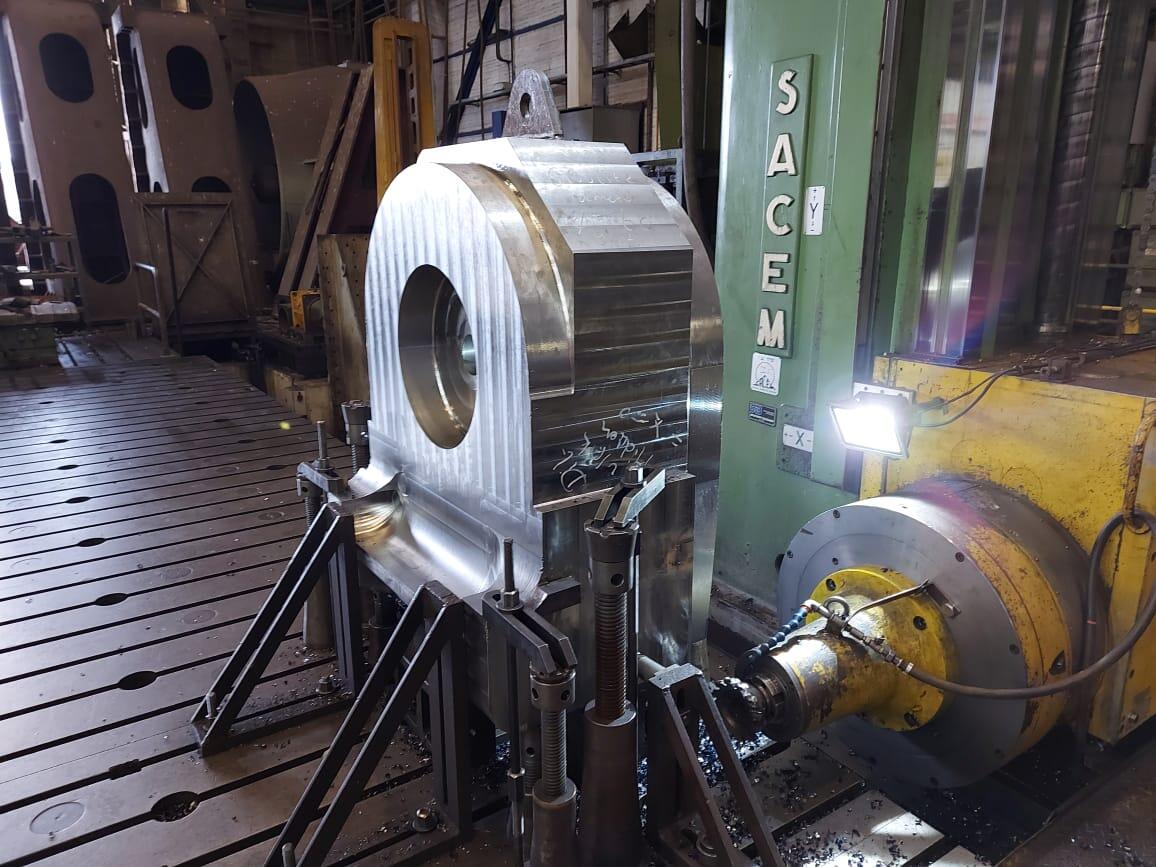

Repairs involved cropping of the rudder blade and refabricating of middle section, supply of cast steel rudder horn pintle bush and processed to dimensions, refabricating of rudder horn pintle section, renewal of rudder stock and renewal of propeller.

Enjoy the slideshow!